Introduction

Scaffolding is an indispensable component of construction and maintenance projects, providing a safe and stable platform for workers to access elevated areas. At the heart of these structures are scaffolding couplers, which play a crucial role in connecting scaffold components and ensuring structural integrity and safety. This article explores the various types of couplers commonly used in scaffolding, their functions, and their significance in maintaining a secure scaffold structure.

1. What Are Scaffolding Couplers?

Scaffolding couplers are specialized devices designed to join scaffold tubes, creating a sturdy and stable framework essential for construction work. These components ensure the strength and integrity of the scaffolding, safeguarding workers and facilitating the successful completion of

construction projects. By understanding the different types of couplers and their applications, construction professionals can assemble scaffolding systems that meet safety standards and project requirements.

2. Types of Scaffolding Couplers

Scaffolding couplers come in several varieties, each serving aspecific purpose in the construction of a scaffold system. Here, we delve into the most common types and their applications:

2.1 Right-Angle Couplers

Right-angle couplers, also known as double couplers, fixed couplers,90 degrees couplers, are used to join two scaffold tubes at a 90-degree angle, forming a perpendicular connection. They are fundamental in constructing the basic framework of scaffolding structures, providing essential stability and support. These couplers are critical for ensuring that the scaffolding can bear the necessary loads and maintain its structural integrity during use.

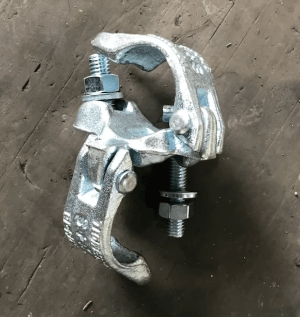

2.2 Swivel Couplers

Swivel couplers enable the connection of scaffold tubes at anyangle within a 360-degree range. This versatility makes them ideal for constructing complex scaffold configurations that require flexibility and adaptability. Swivel couplers feature two clamps that can be tightened to secure the tubes firmly, ensuring a stable connection that can withstand various loads and stresses.

2.3 Sleeve Couplers

Sleeve couplers, often referred to as joiners or internalcouplers, are used to connect scaffold tubes end-to-end. These couplers slide over the tubes and are secured using bolts or pins, creating a robust connection. Sleeve couplers are essential when scaffolding requires longer spans or when two tubes need to be joined to achieve the desired length, ensuring stability across extended sections of scaffolding.

2.4 Putlog Couplers

Putlog couplers, also known as single couplers, serve the purposeof attaching transoms or putlogs to ledger tubes. With a single clamp mechanism, they effectively secure the putlog or transom tube to the ledger tube, providing stability and support. Putlog couplers are typically used in scaffolding configurations where a platform is constructed on one side of a structure, such as during brickwork.

2.5 Girder Couplers

Girder couplers, often referred to as beam couplers or beamclamps, are specifically designed to connect scaffold tubes to structural beams or girders. These couplers employ a robust gripping mechanism that attaches to the flanges of the beam, creating a secure connection. Girder couplers are vital when scaffolding is required to be erected on or around existing structures, providing a reliable anchoring point. They are available in fixed girder couplers and swivel girder couplers to realize different fuctions. They are always used pairs.

2.6 Board Retaining Couplers

Board retaining couplers, also called board clamps or toe-boardcouplers, are essential for securing scaffold boards or toe-boards to the scaffold structure. These couplers typically feature a hook or gripping mechanism that firmly holds the boards in place, preventing accidental displacement. Board retaining couplers are crucial in maintaining a safe working platform, ensuring that workers can move and operate confidently without the risk of boards slipping or shifting.

3. Uses and Applications

Scaffolding couplers find extensive applications across various industries, including construction, maintenance, and event staging. They are critical in the construction of high-rise buildings, installation of façades and curtain walls, maintenance and repair work on tall structures, industrial maintenance, and access solutions, as well as event staging and temporary structures. The versatility of scaffolding couplers makes them indispensable increating safe and efficient working environments.

4. Safety Considerations

Safety is paramount when working with scaffolding couplers. Hereare some key considerations to ensure a safe working environment:

· Ensure that couplers are properly secured and tightened to prevent accidental dislodging.

· Regularly inspect couplers for signs of wear, damage, or corrosion, and replace them if necessary.

· Adhere tolocal regulations and industry standards for scaffold assembly and usage.

· Provide adequate training to workers on the correct assembly and use of scaffolding couplers.

· Conductregular inspections and maintenance of scaffolding structures to identify and

rectify potential issues.

5. Frequently Asked Questions (FAQs)

· Can different types ofscaffolding couplers be used together?

Yes, different types of scaffolding couplers can be used together, depending on the specific requirements of the scaffolding structure.

· Are scaffolding couplersreusable?

Yes, scaffolding couplers are typically designed to be reusable. They are made from durable materials such as steel or aluminum, which are known for their strength and longevity.

· What are the weight limits forscaffolding structures?

The weight limits forscaffolding structures can vary depending on several factors, including the type of scaffolding system, the materials used(forged steel or pressed steel), and the specific regulations in place.

· How often should scaffoldingcouplers be inspected?

Scaffolding couplersshould be inspected before each use and at regular intervals throughout the project to ensure their continued safety and functionality.

· Are there any alternatives toscaffolding couplers?

Yes, alternatives include system scaffolding, frame scaffolding, cuplock scaffolding, and kwikstage scaffolding, etc..

6. Alternatives to Scaffolding Couplers

While traditional scaffolding couplers are widely used, several alternative methods and components can be employed in specific situations:

· Ringlock System Scaffolding: Utilizes prefabricated verticals, horizontals and components that connect without couplers, offering faster installation and enhanced stability.

· Frame Scaffolding: Uses prefabricated frames and cross braces and other components, providing versatility for complex configurations.

· Cuplock Scaffolding: Employsa unique cup and blade mechanism for rapid assembly and high load-bearing capacity.

· Kwikstage Scaffolding: Featuresa wedge-locking mechanism for quick and secure connections.

Conclusion

Scaffolding couplers are vital components in ensuring the safetyand stability of scaffolding structures. By understanding the various types of couplers, their applications, and safety considerations, construction professionals can build robust scaffolding systems that meet regulatory requirements. Remember to prioritize safety, conduct regular inspections, and provide adequate training to workers to ensure the successful completion of construction projects.

Tuopeng Scaffold: Your Premier Manufacturing Partner

As a reliable supplier of scaffolding couplers, Tuopeng Scaffoldoffers a wide range of products that meet international standards and cater to diverse construction needs. With a focus on innovation and customer satisfaction, Tuopeng Scaffold ensures that you receive top-quality products with competitive pricing and fast delivery. Choose Tuopeng Scaffold for your scaffolding solutions and experience unparalleled factory excellence and supply advantages.